Atlas Copco | Ergonomic use

How could an industrial grade electric angle grinder be designed to nudge the user to work in a more ergonomic way?

5 weeks | Individual Project | Umeå Institute of Design | 2023

Brief

To design with the form language of an existing brand and learn to evaluate the ergonomic aspects of a design.

Tools & methods

User interviews and observations

Desktop research

Motor package analysis

Ergonomic analysis

Desktop research

Motor package analysis

Ergonomic analysis

Blender

Process

We started out by visiting three local workshops around Umeå where we interviewed and observed the users to get an insight into how they use the angle grinder and what challenges they experience. We then tried out the angle grinder for ourselves, expanded our understanding with desktop research and analysed the findings.

50% of vibration-exposed individuals are affected by neurovascular injuries. The impact of these nerve injuries forces the affected individuals to change their job, and the impact on their hands and fingers, might be so severe that they are no longer able to do every-day things like closing shirt-buttons or shaving.

Atlas Copco is an industry leader when it comes to the physical aspects of ergonomics, but what if they could work with changing behaviours?

Mapping user insights

When users add excessive manual pressure it increases the amount of vibrations that are transfered into the hands and arms.

> So what if we could nudge the user to work in a more ergonomic way?

Ideating on interactive elements

Form & graphics ideation

Based on the form vision, the package and the technical features.

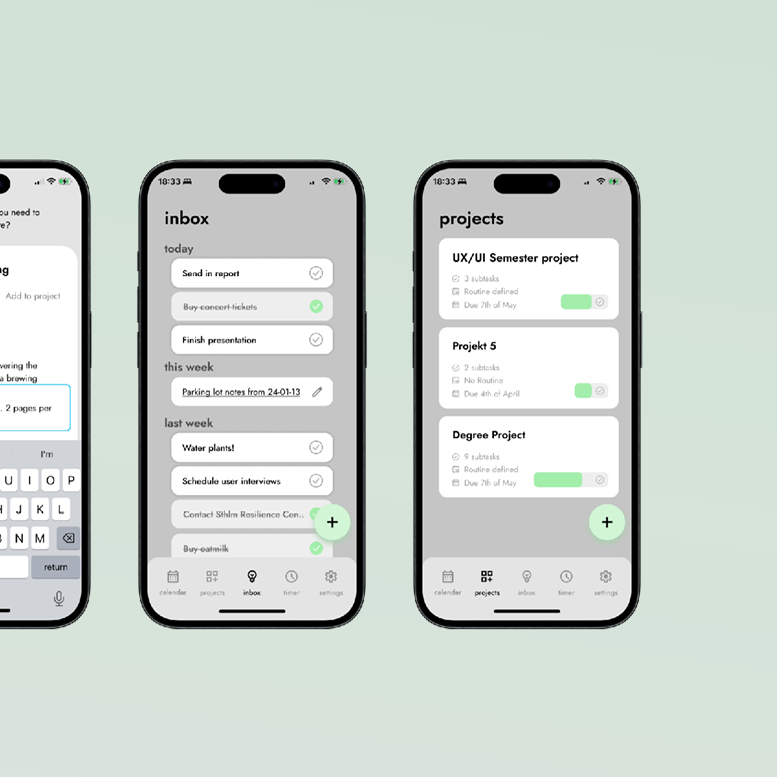

Final Concept - nudging a more ergonomic use

The angle grinder aims to change the users behaviour, using light signals and decreased speed when too much manual force is used.